Are you struggling to keep up with the common inverter problems? Struggling to identify and troubleshoot these issues? Then, this article is a must-read for you!

Here, we will provide step-by-step instructions on how to quickly diagnose and repair inverter issues. So, let’s get started!

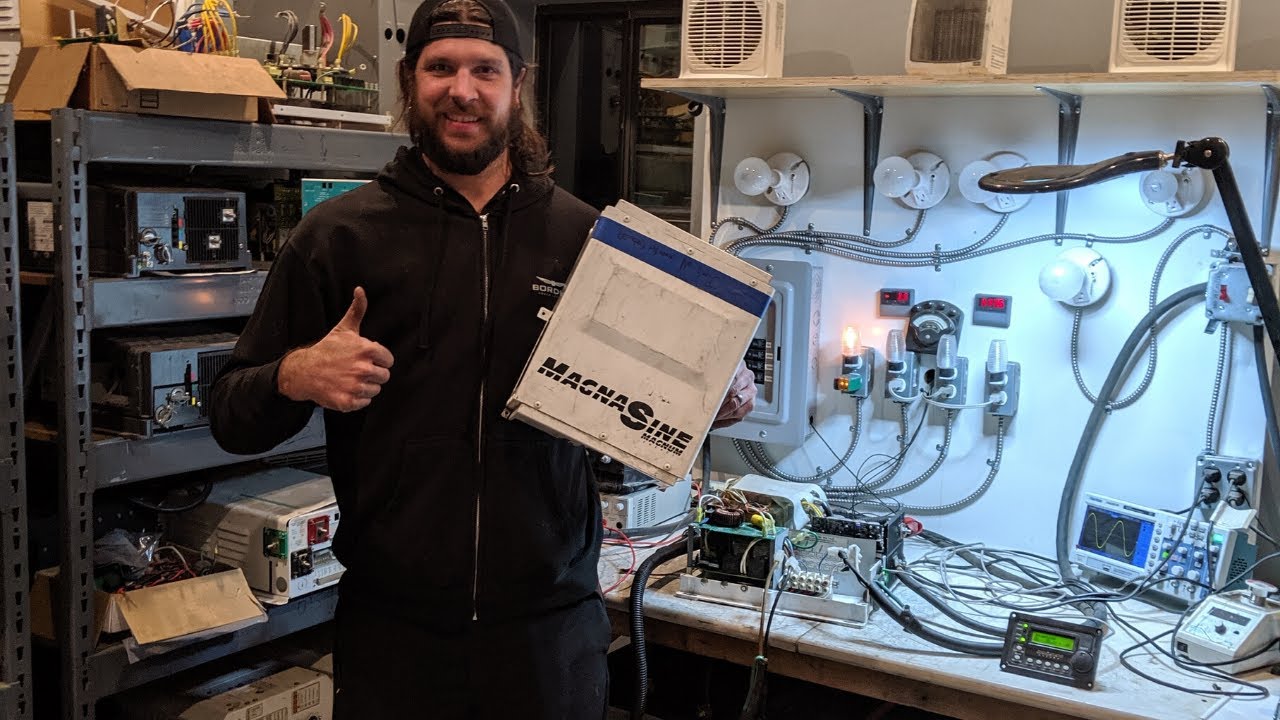

This article discusses how to troubleshoot common inverter problems. An inverter is a device used to convert DC (direct current) electric power into AC (alternating current) power. Inverters are commonly used in solar energy systems and marine applications, as well as for various other off-grid power supplies.

Although the operation of an inverter is quite simple, there may be times when it does not operate correctly due to issues with its components or wiring. The following guide will offer an overview of potential problems and remedies related to these essential devices.

Definition of Inverters

An inverter is an electrical device used to convert direct current (DC) into alternating current (AC). The generated AC power frequency, voltage and number of phases is determined by the type of inverter being used. Inverters are usually utilized in a variety of applications including energy efficiency, solar energy systems and marine applications.

Inverters are composed of electronic components such as transistors, diodes and capacitors, which form the circuitry needed to change the current from DC to AC. In order for any system or equipment that utilizes electricity to function properly, it needs a stable power source in order to run without errors or failures. The stability of this power supply depends heavily on the proper installation and functioning of your inverter systems. Troubleshooting issues with an inverter can be tricky as there are many factors such as voltage fluctuations, incorrect installations and system malfunctions that can cause problems.

To properly troubleshoot an inverter, it’s important to first understand how these devices work and what the common signs of malfunction may include. This guide will provide benefits in understanding what types of issues may arise and how they can be fixed before they lead to more costly problems down the road.

Importance of Inverters

Inverters play an important role in providing reliable and sustainable power to businesses and households. They are used to provide continuous power supply from a variety of sources, including solar and other renewable resources, for residential and commercial purposes.

Inverters convert DC current from a battery or other source into AC current that can be used for household or business applications. This means that it will ensure uninterrupted access to electricity even during blackouts or brownouts, making them essential devices in homes or businesses that cannot afford to have extended periods of outages.

Additionally, inverters are becoming increasingly popular due to their capability of allowing consumers to save money on energy costs by relying more heavily on renewable energy sources. Solar inverters, for example, convert the DC power coming from photovoltaic (solar) panels into AC current that can be used throughout the property. This helps reduce electricity costs and negative environmental impacts associated with traditional energy consumption methods by allowing households and businesses to rely more heavily on clean energy sources like solar power.

Common Inverter Problems

Inverters play an important role in turning the power from batteries or solar panels into AC current to be used by devices such as lights, appliances and air-conditioners. Inverters, however, can be prone to various problems due to their increased usage. This article will explore some of the common inverter problems that may arise and provide suggested troubleshooting steps.

- Voltage Drop: One of the most common issues faced with inverters is a sudden drop in output voltage or frequent fluctuations. This can occur due to excessive load being placed on the inverter’s capacity causing it to overload and abruptly shut down. To resolve this issue, it is important to check all wiring connections, evaluate system components for any visible damage or corrosion, and adjust inputs if necessary (e.g., reduce load) by unplugging component pieces if need be.

- Heating/Overheating: Another issue commonly faced with inverters is increased levels of heat being generated during operation which can lead to a premature shutdown of the instrument if not addressed in a timely manner. To mitigate this issue, make sure fan blades are clean and free of debris as well as any air filters are clear; also ensure proper ventilation around installing location such as positioning away from other devices or keeping away from corners that could hinder airflow; Lastly ensure there aren’t any loose wiring connections further causing increased resistance leading higher levels of heat build-up.

- Tripping Circuit: Fluctuating voltages due unwanted spikes can cause circuit breakers that protect inverter against short circuiting and overload tripping after regular intervals leaving one perplexed when trying out troubleshoot circuitry hence reaching out towards technician should be taken into consideration followed further exploring into circuit if fault lies within circuitry itself or anywhere else on board generally paying attention towards minute details especially near wiring has been done his are generally place where lot many errors takes place. If fault lies within board itself then seeking professional help should be taken into account.

Thus these were few common problem related towards utilization of instead along with its respective solutions, should not possible symptoms escalates then immediate assistance should be taken otherwise slight reduction over usage might do trick.

Overheating

Overheating is an all too common problem with inverters. It can be caused by poor ventilation or an overworked inverter. To troubleshoot an overheating inverter, first check to make sure that the unit is located away from any sources of heat such as a heater, radiator, or another electronic device. If there are other devices near the inverter, try relocating it so that they are further apart.

You should also check to make sure that the air vents and louvers are clear and unobstructed. Dust buildup can clog the vents and reduce the flow of air, resulting in overheating. Clean out any dust or debris inside the vent openings with compressed air.

Finally, make sure that your current load is within the manufacturer’s recommended limits for your inverter model and size. If you are running multiple loads at once, see if switching off one at a time helps reduce overall heat generation to an acceptable level.

Output Voltage Fluctuations

Voltage fluctuations are a common issue that can be caused by a variety of different factors, so it’s important to identify the source of your problem before attempting to fix it. The first step when troubleshooting output voltage fluctuations is to adequately check all wiring connections, as loose wires can cause the inverter not to operate correctly. Ensure that the power cable is connected properly, and verify there are no breaks in the cable. If the wiring checks out ok, then there could be an overload or over-voltage condition occurring which will require adjusting parameters within the inverter’s menu options.

If you suspect an overload or over-voltage condition is occurring, check if your system is running higher than normal levels of amperage or voltage; this could potentially cause voltage swings and should be addressed as soon as possible. If you find there are no problems with high levels of current draw or voltage, the inverter itself may be malfunctioning due to faulty components. In this case it may need to be replaced completely.

In any case, fluctuations in output voltage are a serious issue and should be inspected and addressed immediately for best performance and longest system life.

III. Troubleshooting Common Inverter Problems

Inverters often provide power to large loads, such as air conditioning units, and can malfunction when the load becomes too great or when there is a problem with their wiring. The following tips can help you identify and troubleshoot common inverter problems.

- Check the fuse in the AC circuit – Usually located inside of the fuse box, these are designed to protect both your appliance and your inverter from overloading. If it appears to be damaged or blown, replace it immediately before attempting any further repairs.

- Check wiring – Double check that all wires are connected properly in accordance with manufacturer recommendations–particularly if you have recently moved the inverter or changed its location–as this can sometimes cause performance issues or complete loss of power delivery capabilities.

- Test voltage output – Depending on your model of inverter, you should have access to various ports that allow you to test voltage output with a multimeter device or other measuring tool of your choice. Consult your manual for further instructions on how to perform this type of testing procedure in order to accurately diagnose potential problems.

- Listen for strange noises – Longer-term operation may produce grinding sounds coming from the moving parts inside that rust has damaged beyond repair; these devices should be replaced as soon as possible in order to continue delivering performance at a safe level of operation.

Overheating

Overheating is one of the most common problems with inverters. This happens when the internal temperature of the inverter rises beyond optimal levels and causes it to shut down temporarily.

To prevent this from happening, make sure that you clean any dust or dirt particles from the cooling fans regularly, and keep the area around it cool and free from any heat producing sources. Additionally, check your system for loose connections and correct power supply issues if necessary.

If all these measures don’t work, it is advisable to contact a professional for further help.

Output Voltage Fluctuations

Output voltage fluctuations in an inverter are a very common problem and can be caused by a number of factors. If the output voltage is too high, it could indicate a faulty rectifier or transformer, or that the internal components of the inverter are overheating due to improper cooling. If the output voltage is too low, it could be due to an issue with either the battery or controls on the time of delivery of electricity.

To rectify these issues, you should first check all connections and check for any visible signs of damage. You should also inspect all cooling vents to ensure that they are unobstructed and working correctly. It is important to ensure that your inverter has been switched off before any work is carried out on it to avoid shock hazards. If your inverter is still not functioning as expected after these initial checks, you may need to contact a qualified engineer for further investigation and servicing.

Preventive Maintenance for Inverters

Performing preventive maintenance on your inverters can significantly reduce the risk of unexpected failures, saving you time and money. A good preventive maintenance program should include regular inspections and tests as well as operating checks.

Inspections may include evaluating the inverter’s circuit boards, power supply connections, power connections, protective covers, cracks in the housing, screws and fasteners to ensure they are secure and free of corrosion. Additionally, inspect the wiring for evidence of corrosion or damage to the coverings. Most inverter manufacturers provide a list of preventative maintenance tasks to ensure optimal performance.

Tests should be run on all components of the system including battery discharge tests, temperature tests and wire resistance tests. You can set up these tests when setting up your system or you can use a testing device regularly for ongoing preventive maintenance checks.

Operating checks should be performed daily to verify that everything is running normally with no strange sounds or odors indicating problems with any part of the system. Also check for signs of stress or excessive wear such as brittle wires or loose connectors which could lead to equipment meltdown or failure if left unchecked. Regularly check all connections for signs of poor contact that could cause an open circuit which causes strain on parts due to excess current circulation.

Regular Inspection

Regular inspection is critical for inverter maintenance and helps to identify possible problems before they become more serious. Depending on the usage and environment of your inverter, regular inspections should be conducted at least once a year to check for visible damage, such as power cable damage and fan wear/tear, as well as cleaning all cooling components such as ventilation grills, air filters and fans blades.

Where possible, also verify all power settings (voltage, current) of the inverter. If any significant changes in performance are identified during these yearly inspections, further investigation may be necessary.

Cleaning

When troubleshooting an inverter, it is important to inspect the unit and clean any visible contaminants or debris that may be preventing it from working properly. If your inverter has a fan, ensure that it is clear of dust, dirt or other materials as these will restrict airflow and cause the fan to work inefficiently.

A buildup of dirt can also cause the motors inside the unit to overheat, thus causing further damage over time. If possible, use compressed air to quickly remove surface-level debris and then use a soft cloth and vacuum cleaner for deeper cleaning.

This should be done at least twice a year in order to prolong the life of your inverter and reduce any potential faults in its performance.

Conclusion

By following the steps outlined in this guide, you can diagnose and address common issues with your inverter. To ensure that your inverter will continue to operate smoothly over time, you should refer to the user manual that came with it, as well as take proactive steps to prevent unnecessary stress and strain on it. Regular cleanings and maintenance will go a long way toward keeping your inverter in good condition.

It’s also recommended that you establish a relationship with an inverter repair professional who is familiar with the model type that you own, so they can be of assistance when needed. With basic knowledge, the right tools and some patience, however, many of these troubleshooting issues can be addressed without expensive outside help.

See Also-

- Best Power Inverter For Truck

- Best Power Inverter

- Best Pure Sine Wave Inverter

- Best RV Inverter 2023

- Best Solar Inverter 2023